MILLING FROM THE GROUND UP

LafargeHolcim Côte d’Ivoire has successfully installed ball mill No 6 at its Abidjan plant adding 1Mta grinding capacity. This was a complex project to recycle a pre-used mill from a Spanish plant and reinstall it on a smaller footprint in west Africa.

by Celine Mansuy, LafargeHolcim, Côte d’Ivoire

With 8.5 per cent GDP growth in 2016, Côte d’Ivoire is a driving force in west Africa. The many development projects in the country have led to an increase in the demand for cement and the arrival of new competitors in a market where LafargeHolcim occupies an historically leading position.

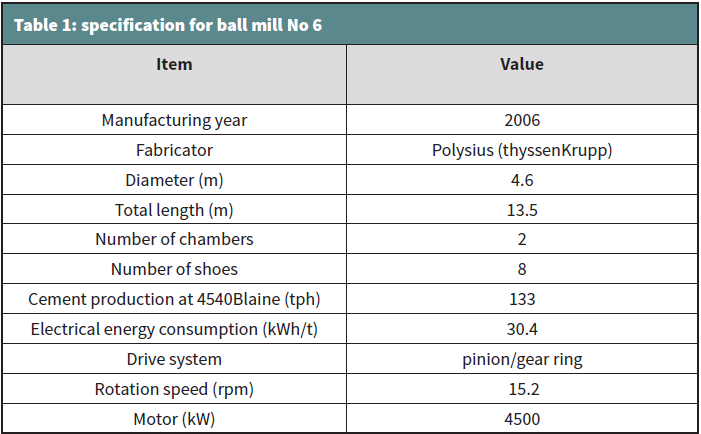

To face this challenge, and the emergence of new players, LafargeHolcim Côte d’Ivoire is deploying an ambitious development plan. With its 4.5MW motor, the company now operates the largest horizontal ball mill in French-speaking west Africa. Originating from a former Holcim cement plant in Spain, the large ball mill has been re-erected piece by piece in Abidjan in recent months and is now in operation.With the commissioning of this new mill, we have the largest production capacity in Côte d’Ivoire. This capacity increase is one of our answers to better serve the Ivorian market,” said Xavier Saint- Martin-Tillet, CEO of LafargeHolcim Côte d’Ivoire.

With a total project cost of €23m for a cement production of 1Mta, ball mill No 6 has been a profitable capex project in west Africa.

Construction and first cement

The construction started with piling activities, which were completed in March 2016. The total length of the underground piles is 1.6km. Five months later, the surface foundations were ready. The mechanical assembly work could then begin with erection of the building in structural steel and installation of the mill. Additional equipment was progressively installed and the first cement was produced in September 2017. Ball mill No 6 will enable LafargeHolcim’s Abidjan grinding plant to increase the output of its Ciment Bélier-branded cement which is available in a variety of types, including the ‘Classic’ CEMII/B-L 32.5R, ‘Duracim’ CEMIII/A-S 32.5N and 42.5N, ‘Extra’ CEMII 42.5R and ‘SuperPro’ CEMI 42.5R.

The different types of cement serve various applications, including houses, buildings, infrastructure, roads, ready-mix and precast products. An applications laboratory also supports customers’ specific needs by producing special formulas.

The technical challenge and health and safety

Substantially increasing the capacity of the plant from 1.5Mta to 2.5Mta with the same footprint was a key challenge of this project. The limited available area on site resulted in a high building (over 40m in height) that involved complex planning to ensure safe assembly.

Such an approach required increased attention to maintain safe erection and the careful movement of heavy equipment under tight control. Despite the challenges of the project, over 300,000 work hours were successfully logged without any lost time injury (LTI).

“The greatest success of this project was its completion with zero harm to our people. LafargeHolcim’s overreaching value is health and safety so we are proud to deliver the B6 project without accident,” said Mr Saint-Martin-Tillet.

He continued: “This capacity increase is one of our solutions to better serve the Ivorian market. However, we have to keep in mind that this investment alone is insufficient without a quality team.

Our team is able to apply the best global safety standards and also continuously improve the performance of the facilities in terms of productivity, quality and environmental performance.

Whether it’s health and safety or technical expertise, our success definitively starts with our people.”

Palletising and cement distribution

Seasonality of demand in Côte d’Ivoire and supply difficulties in some remote areas of the countryside are often the cause of challenges between producers and customers.

This is the main reason that pushed LafargeHolcim to invest in the first palletisation system in Côte d’Ivoire – a €5m project that enables the cement manufacturer to load all of its products on the same truck and ensure a timely supply to customers. It is a time-saving and differentiating solution for cement customers as previously trucks were loaded directly from the silos, in a tight flow.

To make cement available throughout the Ivorian territory, the company created a local distribution network for small constructors and end users called Binastore.

Since its creation in November 2016, Binastore Côte d’Ivoire now has 130 sales outlets throughout the country and offers more than 400 product references in addition to LafargeHolcim’s local cement brand, Ciment Bélier. The goal of the network is to reach 300 points of sale by 2019.

Meeting the affordable housing target

In recent years the LafargeHolcim Group has been developing affordable housing initiatives with the aim of building around 2m housing units worldwide by 2020.

In French-speaking west Africa, LafargeHolcim Côte d’Ivoire is a pioneer in helping to address the growing challenge of providing decent, affordable and sustainable housing. The PROBAT real estate offering launched in October 2017 is a solution to a prevalent issue for Ivorian households. These affordable homes, with prices varying between €14-22,000 effectively link low-income households, housing finance, materials and construction through one scheme. Three hundred homes will be built by the end of 2017, with a target of 3000 homes per year thereafter.

All these initiatives support the renewed vitality of the Ivorian economy and maintain LafargeHolcim’s leading position in a competitive environment.

TÉLÉCHARGER L’ARTICLE PUBLIÉ DANS LE NUMÉRO DE DÉCEMBRE 2017 D'INTERNATIONAL CEMENT REVIEW